Copper tubes - High pressure (K65 & TALOS XS)

- Certification guaranteed

- Flexible and long-lasting cooperation

- Fast delivery from stock

High pressure tubes (K65 & TALOS XS)

Growing concerns about the environmental impact of hydrofluorocarbon (HFC) refrigerants and tougher environmental regulations have led to a re-emergence of carbon dioxide (CO₂) refrigeration systems. CO₂ Refrigerant (R-744) is used as a working fluid in many climate control systems, in applications such as commercial refrigeration, hot water pumps, vending machines, etc. The supermarket industry in particular is implementing an ecological and efficient retail concept by successfully embracing advanced CO₂ refrigeration technologies developed by manufacturers of cooling systems.

However, due to the physical properties, cooling systems based on CO₂ require a much higher pressure compared to conventional systems. The design pressure of such systems can be 120/130 bar in the trans critical cycle. CO₂ meets the demand for low global warming potential (GWP) refrigerant, but presents challenges in both application and handling. The higher operating pressures and large temperature variations require that all system components, including tubes, are designed accordingly.

Product features

-

Ideally suited for CO2 cooling applications

-

Made from an extra strong copper-iron (CuFe2P) alloy

-

Traditional processing techniques and equipment

-

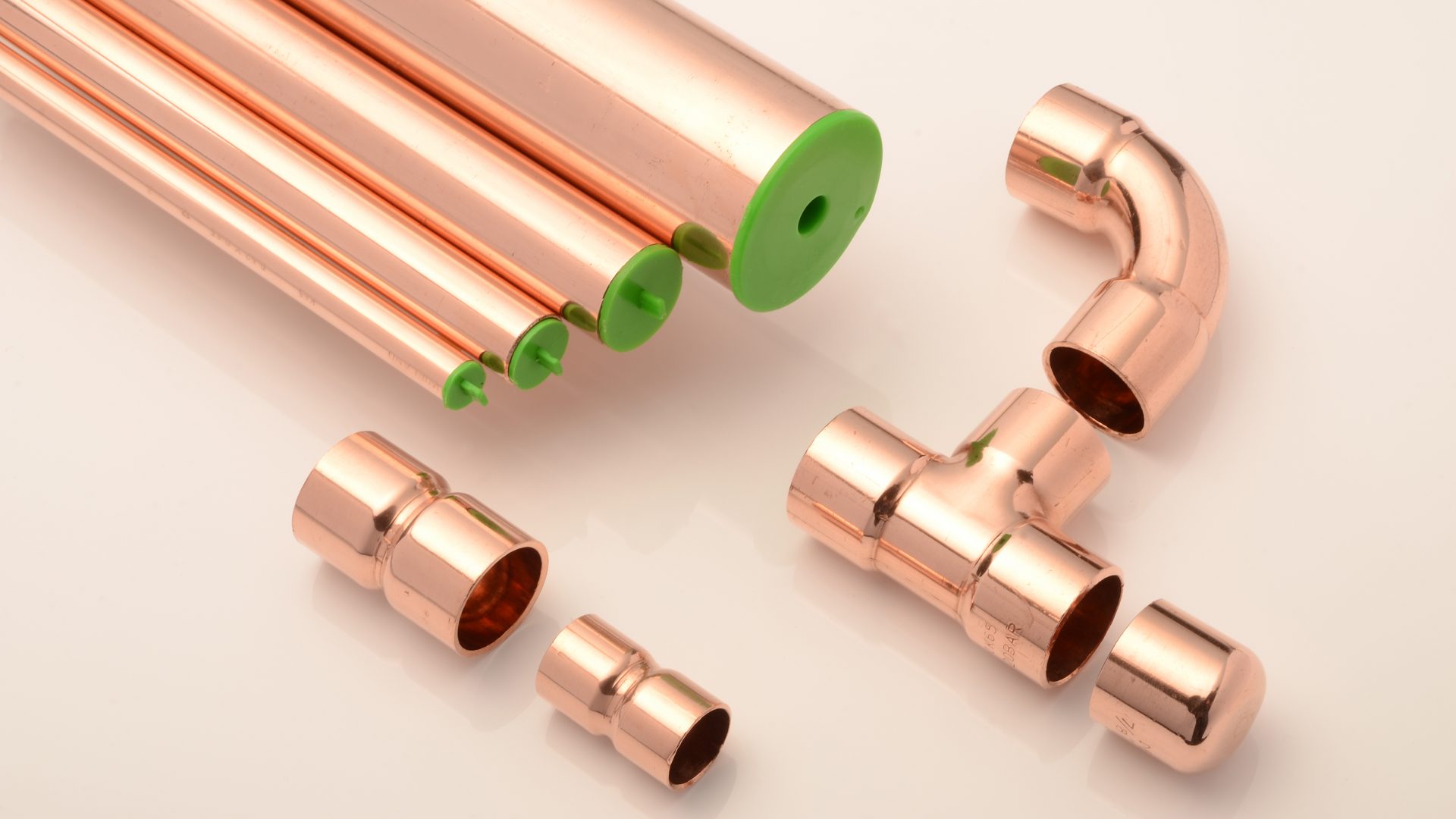

Compatible with existing fittings made from the same alloy

-

Clearly marked and easy to identify

Details

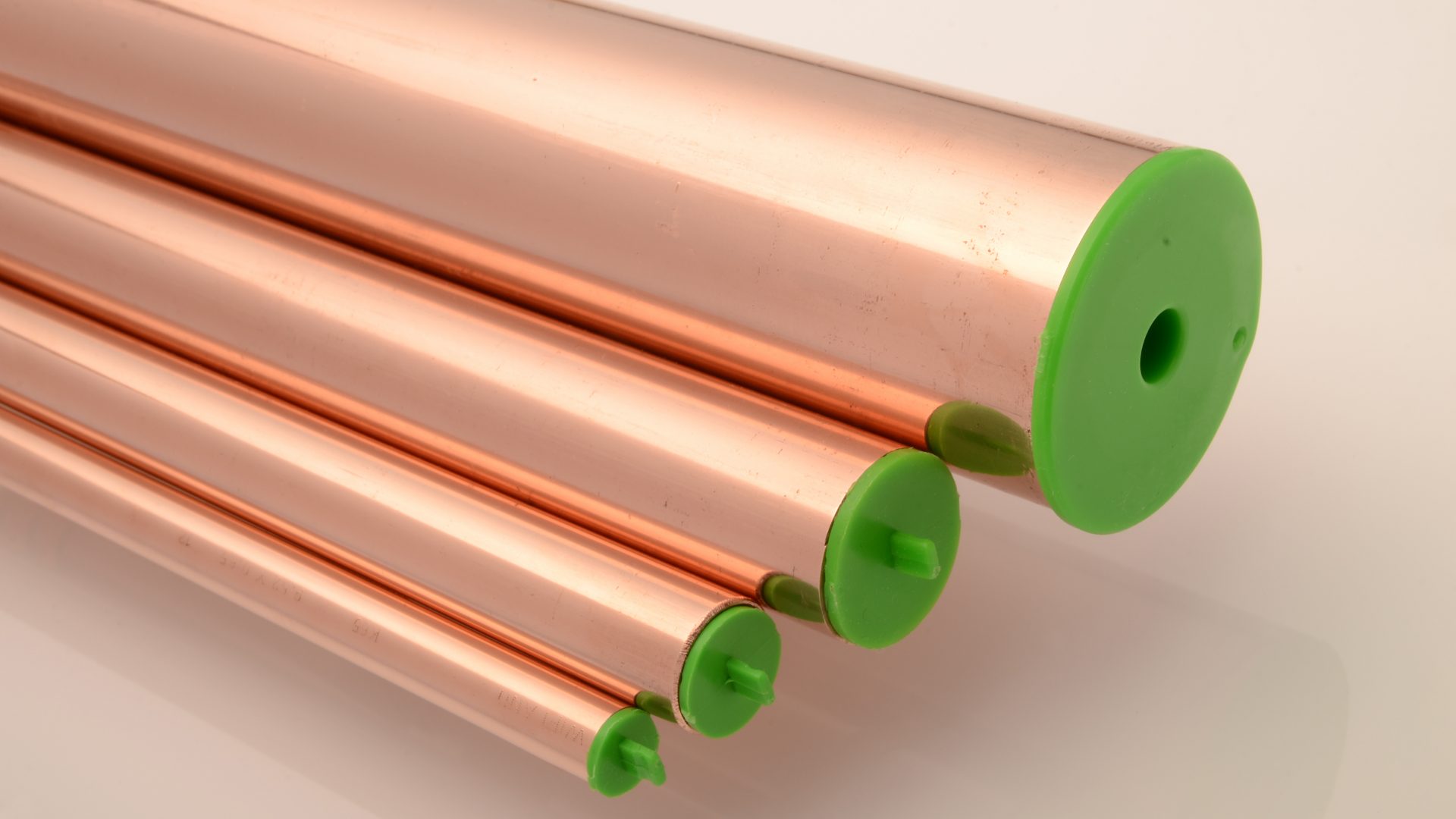

TALOS XS and K65 tubes are manufactured from a high-strength copper alloy (CuFe2P) material to meet the requirements of today’s high-pressure CO₂ systems in refrigeration, as well as other high-pressure HVAC & R applications. These tubes are designed to withstand high operating pressures up to 130 bar.

- Available in straight lengths from 3/8 ”to 2 5/8”

- Packed in shrink film or wooden cases

- With end caps to prevent contamination during storage or transport

Material & specifications

-

Copper-iron alloy (CuFe2P) with chemical composition according to EN12449 (CW107C) and UNS C19400

-

Internal product specifications and cleaned according to EN 12735-1

-

Mechanical properties according to EN 12735-1 and VDTÜV WB567